|

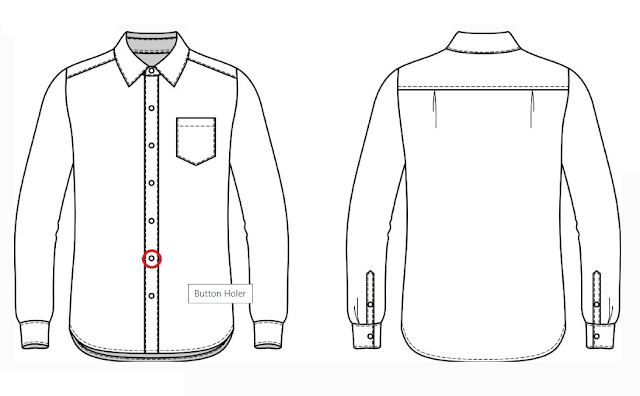

Button Hole Machine |

Uses: A buttonhole machine is a specialized

sewing machine that is widely used in the apparel manufacturing industry for

creating buttonholes on various types of fabrics. Buttonholes are an essential

part of many garments, such as shirts, blouses, pants, dresses, and jackets.

The buttonhole machine is designed to produce precise, uniform buttonholes of

different shapes and sizes, depending on the requirements of the garment.

Here are some of the primary uses of buttonhole

machines in the apparel manufacturing industry:

- Production of shirts: Buttonhole machines

are extensively used for producing buttonholes on shirt cuffs, plackets, and

collars. Shirts are typically produced in large quantities, and a buttonhole

machine can help streamline the production process by creating identical,

high-quality buttonholes in a shorter amount of time.

- Production of jackets and coats: Jackets and coats

often have larger, more decorative buttonholes, which can be difficult to

create using a regular sewing machine. Buttonhole machines are specifically

designed to handle the heavier fabrics used in jackets and coats, producing

high-quality buttonholes that are durable and aesthetically pleasing.

- Production of trousers and skirts: Trousers and skirts typically require smaller buttonholes, which can be

difficult to create manually. A buttonhole machine can quickly and accurately

produce small, neat buttonholes that are essential to the finished garment's

functionality and appearance.

- Production of uniforms: Uniforms for various

industries, such as the military, law enforcement, and hospitality, require a

large number of buttonholes. Buttonhole machines can speed up the production

process, creating consistent and professional-looking buttonholes that are

essential to the uniforms' functionality.

In addition to these primary uses, buttonhole

machines can also be used for creating keyhole buttonholes, bound buttonholes,

and other decorative buttonholes that add an extra touch of elegance to

high-end garments. Overall, buttonhole machines are a critical component of

apparel manufacturing, helping to ensure that high-quality, functional, and

aesthetically pleasing buttonholes are produced efficiently and accurately.

A buttonhole machine cannot be used as an eyelet

hole machine. While both machines are used to create holes in fabric, they are

designed for different types of holes and use different techniques.

A buttonhole machine is specifically designed to

create buttonholes in a variety of sizes and shapes, typically using a zigzag

stitch. Buttonholes require a precisely cut slit in the fabric, and the machine

must be set up to cut the slit before stitching around it to reinforce the

edges.

An eyelet hole machine, on the other hand, is

designed to create round holes with reinforced edges, typically for lacing or

fastening purposes. The machine punches a hole in the fabric and then presses a

metal eyelet or grommet around the hole to reinforce the edges and prevent

fraying.

While some newer buttonhole machines may have the

capability to create eyelet holes in addition to buttonholes, this requires

specific attachments and settings that are not typically included on a standard

buttonhole machine. Therefore, it is not recommended to use a buttonhole

machine as an eyelet hole machine, as it could damage the machine and produce

inconsistent or inadequate results.

A buttonhole machine is a specialized sewing machine

used to create buttonholes on various types of fabric. It is commonly used in

the apparel manufacturing industry for producing shirts, blouses, trousers,

dresses, and other clothing items that require buttonholes.

Some of the key benefits of using a buttonhole

machine include:

- Consistency: Buttonhole machines are designed to

create uniform buttonholes that are the same size and shape. This is especially

important in mass production, where consistency is key to producing

high-quality garments.

- Speed: Buttonhole machines are designed to

sew buttonholes quickly and efficiently, which can increase the production rate

and reduce the overall production time.

- Versatility: Buttonhole machines can create

buttonholes of various sizes and shapes, depending on the type of garment being

produced. Some buttonhole machines can even create keyhole buttonholes or bound

buttonholes, which are more complex and decorative.

Components: A buttonhole machine typically consists of the following parts:

- Bed Plate: This is the flat surface on which the

fabric is placed and sewn.

- Needle: A needle is used to pierce the fabric

and create the buttonhole.

- Feed Dogs: These are the teeth-like mechanisms

that grip the fabric and move it forward as the needle sews the buttonhole.

- Buttonhole Cutter: This is a sharp

blade that cuts the buttonhole open after it is sewn.

- Stitch Length Adjuster: This allows the user

to adjust the length of the buttonhole stitch.

- Tension Adjuster: This controls the

tension on the thread as it is fed through the machine.

- Thread Cutter: This is a blade that cuts the thread

after the buttonhole is completed.

- Control Panel: This is a set of buttons or knobs that

control the machine's settings and functions.

Problems and Solutions: Some common mechanical problems that can occur with a buttonhole machine include:

- Skipping Stitches: This can occur when

the needle fails to pierce the fabric, resulting in incomplete buttonholes.

This can be caused by a dull needle, incorrect needle size, or incorrect thread

tension.

- Birdnesting: This occurs when the thread bunches up

under the fabric, resulting in a tangled mess of thread. This can be caused by

incorrect tension or incorrect needle and thread combination.

- Needle Breakage: This can occur when

the needle snaps while sewing the buttonhole. This can be caused by a dull

needle or incorrect needle size.

- Feed Dog Problems: This can occur when

the feed dogs fail to grip the fabric and move it forward. This can be caused

by a worn feed dog or incorrect feed dog position.

To solve these problems, the following solutions can

be applied:

- Skipping Stitches: Check the needle and

thread tension and adjust them as needed. Make sure the needle is sharp and the

correct size for the fabric being sewn.

- Birdnesting: Check the tension and use the correct

needle and thread combination. Also, ensure that the thread is correctly

threaded through the machine.

- Needle Breakage: Check the needle

size and make sure it is the correct size for the fabric being sewn. Also,

ensure that the needle is sharp and not damaged.

- Feed Dog Problems: Check the feed dog

position and make sure it is correctly aligned. If the feed dog is worn, it may

need to be replaced.

Regular maintenance, including cleaning and

lubrication, can also help prevent mechanical problems and keep a buttonhole

machine running smoothly.

Hot Searches.

1. Buy Industrial Auto Sewing Machine.

2. Auxiliary Machine Ready Stock available for sale.

3. Sewing Machine Layout for your garments factory.

4. Denim Bottom Automation.

5. Shirt Sewing Machine Automation.

Buttonholes are rigid holes in the fabric that goes through the buttons, allowing the piece of fabric to be secured to the other. The raw edges of a buttonhole usually end with stitching. This can be done by hand or by sewing machine. Some forms of frogs, such as frogs, use a loop of cloth or rope instead of a buttonhole. Buttonholes can also refer to flowers worn in a coat or jacket lapel buttonhole, simply known as "buttonholes" or boutonnieres.

|

Common Features of Button Hole Machine.

HIGH SPEED.

DIRECT DRIVE.

SEMI-DRY HEAD.

COMPUTERIZED STRAIGHT BUTTONHOLE MACHINE.

|

Post a Comment